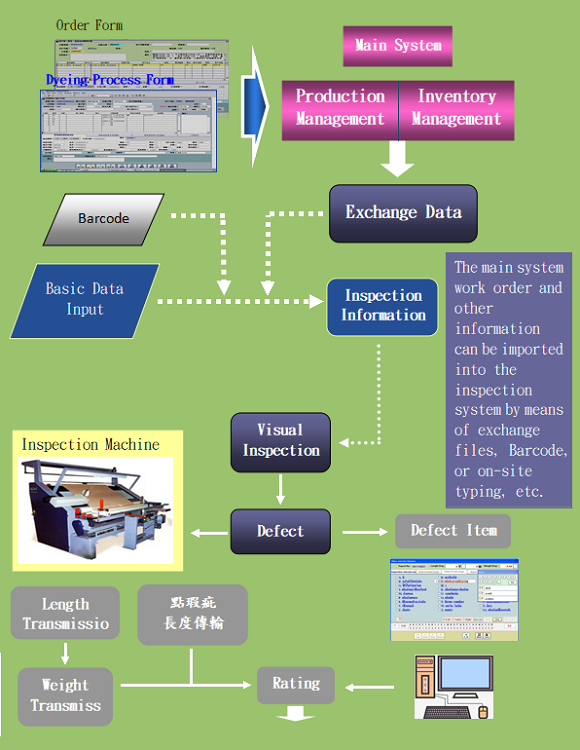

*CFI-sys Characteristic*

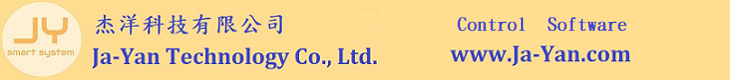

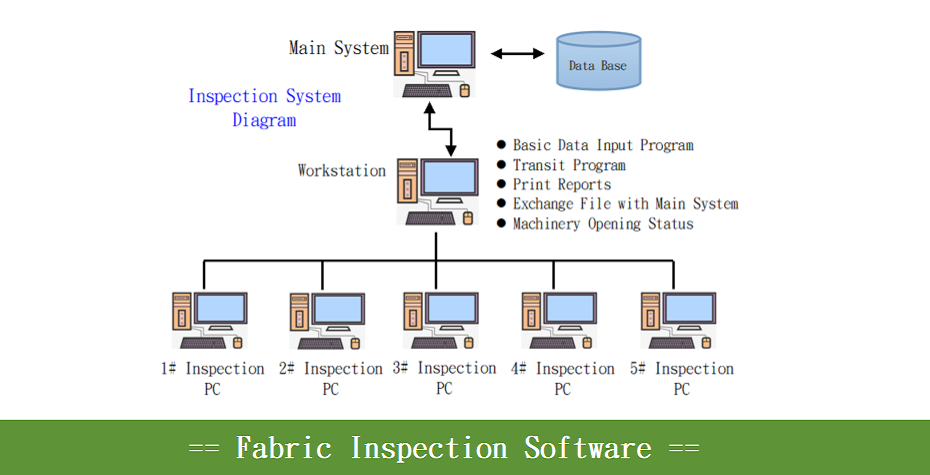

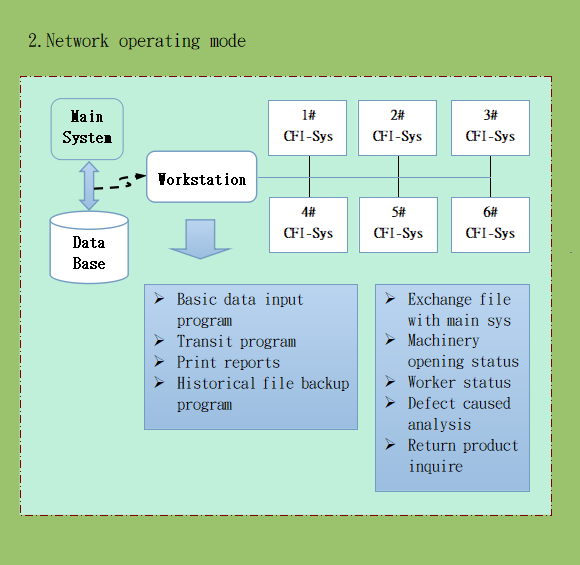

- Single operating mode for CFI-sys shall be input or import the data as manufacture process order on site. For network operating mode, the data can be input, import or download from main system to workstation and then transit to each PC on site, therefore, worker only choice data, defect and number by using windows tool

- Utilize Graphical windows tool

- Integrating the devices of length counter and load cell into CFI-sys, all measurement is in real time

- The length in yards or meters can be printed according to customer requirements, without changing the length counter, and the number of decimal places required for printing length data can also be printed according to customer requirements。

- Each roll can record the length of the fabric and multiple defects in the left, middle and right positions

- The basic data of this system can be set by the customer to define 30 defects, or according to the classification of 30 items, and then according to its classification items, and for each classification item, the number of 10 defects can be set separately, and the total can be Up to 300 defect settings。

- Two language versions, can free choice either one/li>

- The defect name is displayed in the graphical interface window, the operator does not need to remember

- After the grade calculation formula is set in the basic data of this system (the calculation method can be selected according to the customer and the calculation method), once the inspection of the stubborn paper is completed, the system will automatically calculate the cloth according to the customer’s previous setting rules grade

- The inspection process and the end, real-time display of the average operating speed of the fabric inspection machine motor after calculation by the computer

- Single operating mode for CFI-sys shall be input or import the data as manufacture process order on site. For network operating mode, the data can be input, import or download from main system to workstation and then transit to each PC on site, therefore, worker only choice data, defect and number by using windows tool

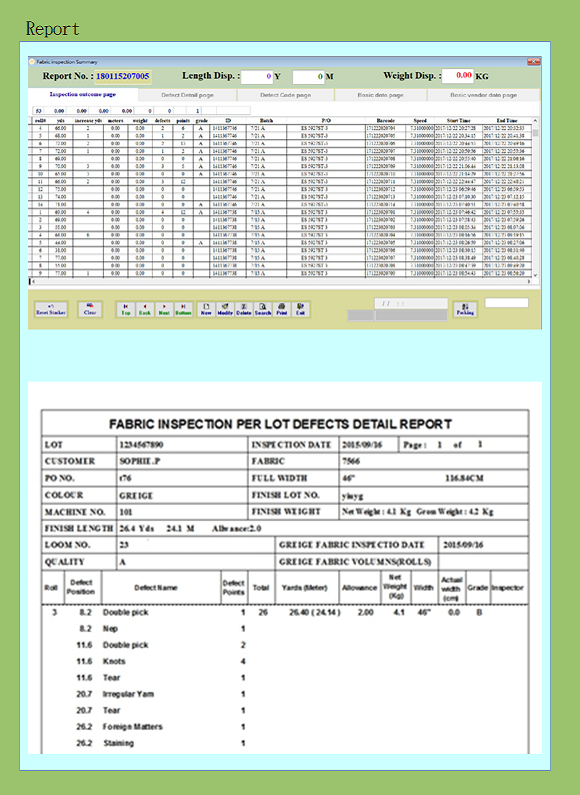

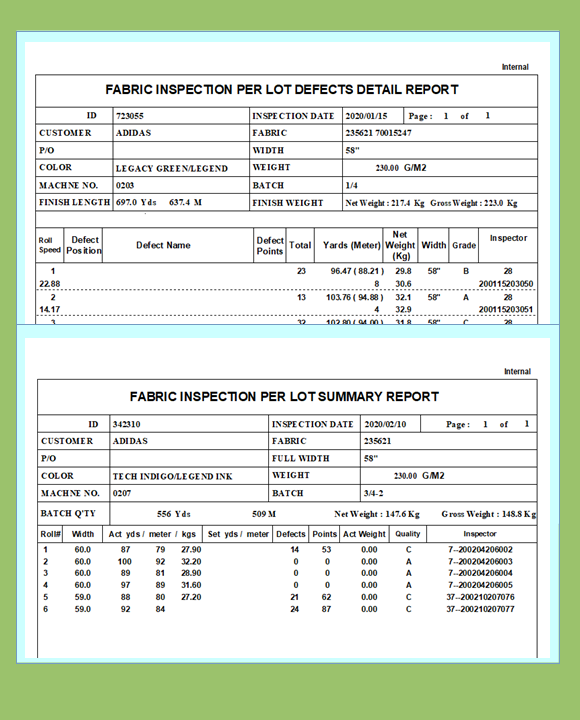

- Printing roll label and QC reports as customer required.

- Machinery opening status :

- Record the working-hours of machineries individually.

- To gather statistics for the opening time of machineries at inspection section that means the ratio of actual working-hours to capacity planning-hours

- Excepting for manage level to handle or review the capacity plan of production, it will be exhibited the status of some machinery whether heavy load/utility rate too high or not

- Worker efficiency status :

- To collect necessary data of each operator everyday such as working-hour/day, average speed/minute and defect quantity/100meter for fabric inspection work

- Reviewing the efficiency and quality of inspection work is from the same manufacture process order in comparison with different worker (the ratio of defect quantity to average speed).

- Defect caused analysis :

- Accumulation of defect quantity from same manufacture process order and/or same fabric type

- After collecting the defect quantity and classifying it into several defect cause such as construction, dyeing, finished work and others) which shall be defined by technician of YRC in advance, and then in comparison with the info record on the manufacture process order to assist QC person to draw a fishbone diagram (cause and effect diagram) for analyzing and/or tracing the key-node of defect caused.

- Return goods inquired :

- According to the roll label of return goods inquire the original inspection status such as worker, happened, time and machinery.